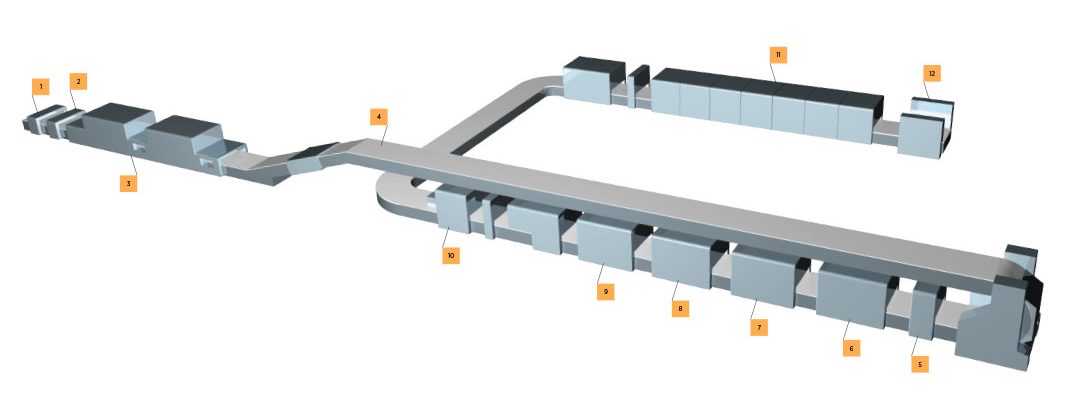

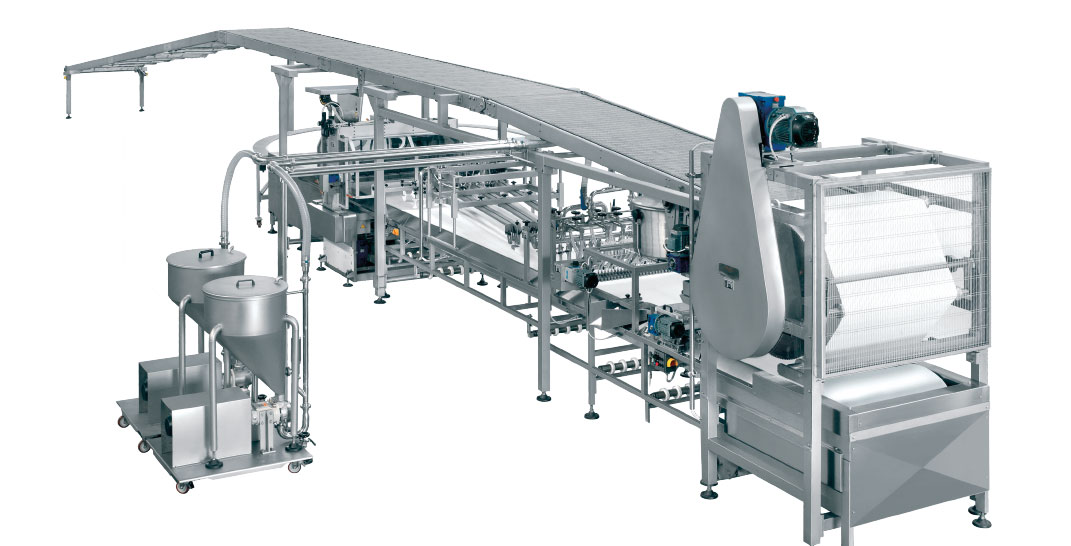

The Tonelli Multiproduct Spongecake Lines are totally automatized, from the mixing of the ingredients to the packaging. They are designed and made to ensure very high outputs and an excellent standardization and quality of the finished product. Each line is able to produce several kinds of products by simply changing settings and accessories.

Sponge Cake Line

- Dosing

- Decoration

- Baking Oven

- Overhead Cooling Conveyor

- Longitudinal Cutting

- Syrup Distribution

- Cream Distribution

- Overlapping

- Rolling

- Transversal Cutting

- Chocolate Enrobing Tunnel

- Packaging

Batter preparation

To start producing on an automatic cake line, first of all raw ingredients have to be incorporated into a batter, then mixed and portioned properly. Batter can be achieved through a variety of equipment and Tonelli provides all the right solutions to obtain the desired product.

Two colour/particles

Is it possible to dose liquid flavouring and colouring matters into pumpable products, either whipped or not, through a Dynamic Colour Mixer.

The colour injection system is located at the head’s inlet in order to mix the particles or colour with the sponge coming from the emulsifier. This machine brings about the presence of a second roller depositor.

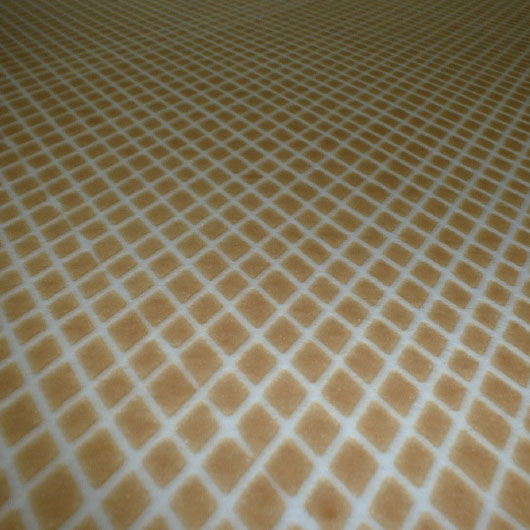

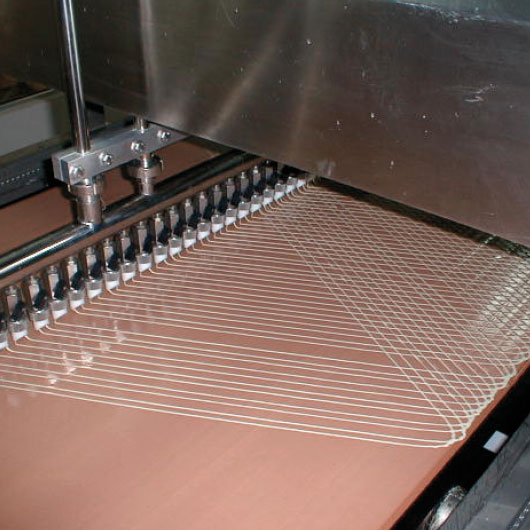

Decoration

The sponge cake can be decorated with icing in different designs and colours, depending on the desired effect: Rhomb, Sinusoidal or Combined.

Cooling

The cooling of the baked sponge cake can be achieved by an Overhead or In Line Cooling Conveyor, depending on the space available: the first allows to reduce space thanks to a first section with 8° slop, carrying a roller to collect the sponge at the oven exit and a second straight one , ending with an overturning head which feeds the cooled sponge to the working table, that runs underneath it.

Two types of conveyors are provided: a stainless steel wire-mesh or a plastic grid model.

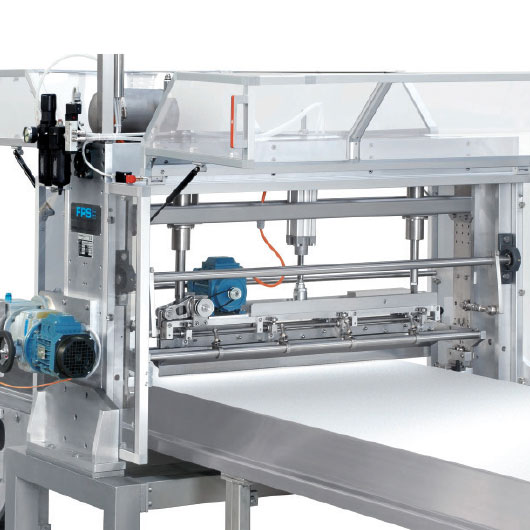

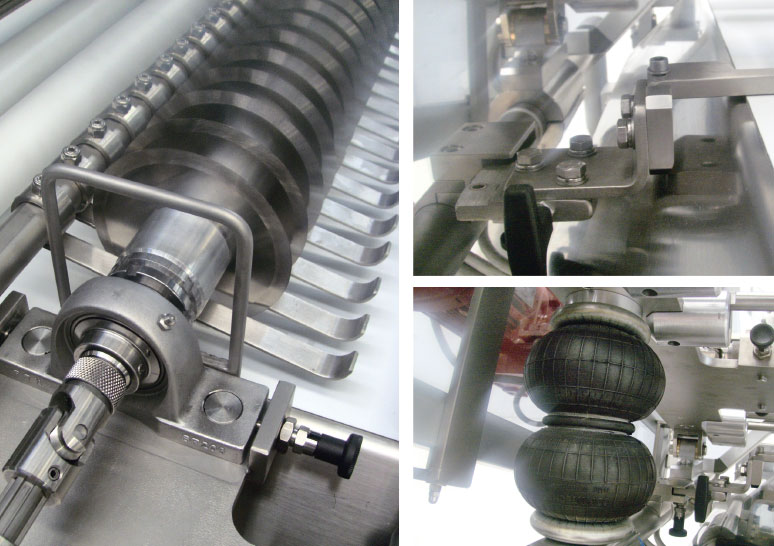

Longitudinal Cutting

The cut is obtained by means of circular blades either smooth or toothed, fitted on a suitable rotary shaft. Each with a precise pitch between the disks, according to the strip size. When a different size of cake is required, the blade holding shaft can be easily replaced.

Cream preparation

The preparation of the cream or filling can be realized through a variety of solutions, each studied for particular applications and final results. Traditional and compact units are suitable for any type of fillings, but it is possible to reach top quality for creams by using pasteurization systems, both in continuous and per batch.

Wetting

Sponge cakes’ wetting consists of an alcoholic or a sugar based solution, that gives the right humidity and even particular flavours to the product. If the customer chooses to produce the syrup by himself, Tonelli provides a complete unit which feeds the distributors directly on the band.

Cream spreading

The filling (cream and/or jam) is spread on the spongecake sheet through a collector which assures a balanced feeding to the set of spreaders beneath. The flow thickness of such spreaders is adjustable by suitable taps.

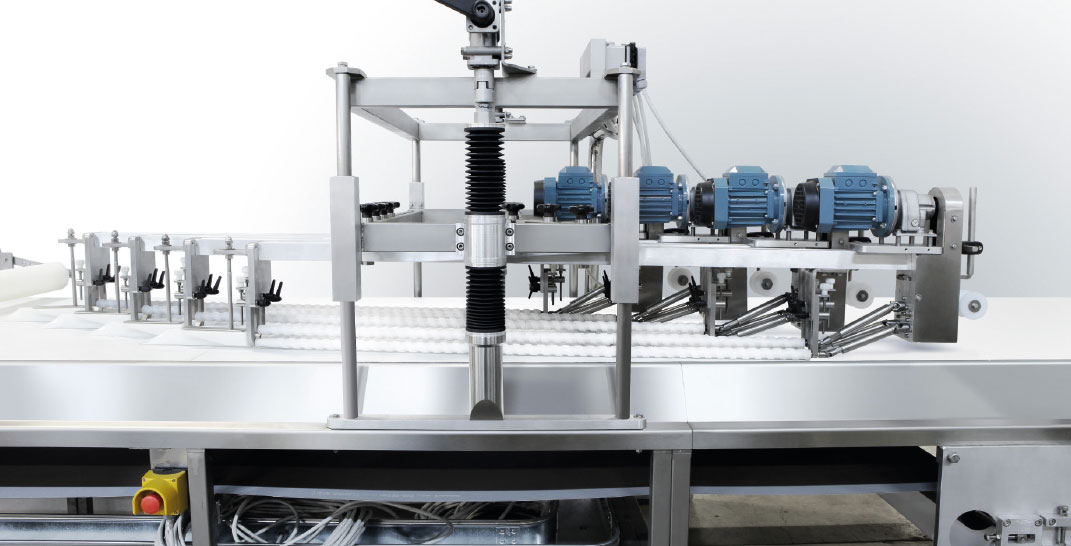

Overlapping

The Layer Cake processing station is composed by an overlapping device with adjustable food-grade polyurethane spades suitably shaped. Their size depends on the product, while the number changes according to the desired number of rows. When the station is not in use, the guide holding bar can be lifted and locked in position. The station is completed by guides and rollers for forming optimization.

Different settings for cakes with two, three or more layers, even with family size can be applied.

Rolling

The automatic rolling up device for Swiss Rolls and Minirolls is designed to roll-up the strips of sponge cake previously cut and filled. The rolling units consist in three knurled plastic screws, shaped for easier picking of the sponge strips. Spades at the infeed of the rolling station lift the sponge strips to facilitate its rolling, while a series of guides at the outlet straightens the rolled product to the band. After this sizing adjustable rollers optimize and uniform the roll size.

Punch cutting

The Automatic Punch Cutter is a special transversal cutter consisting in several blades mounted to obtain particular geometrical shapes into the sponge cake sheet, both with or without filling: round or rectangular sponge bases for cakes, seasonal individual cakes of different shapes. The blades’ disposition is studied to minimize scraps.