This technological solution developed and tested by Tonelli for creams pasteurization is a batch Aseptic Cooking and Cooling system.

Pasteurization

The advantages of such a system are:

- Possibility to easily vary the process parameters.

- More creamy, smooth and homogeneous texture,due to lower mechanical stress when mixing.

- Reduced loss of product on production’s start and stop.

- Reduced washing and sanitizing times.

- The whole cooking/pasteurizing cycle is performed entirely in the batch and it is very rapid.

- Reduced cooling times, thanks to the under vacuum working condition.

- The final cooling takes place in a double scraped surface heat exchanger.

- Pasteurizing creams highly helps improve their hygienical quality, while extending the cake’s shelf-life.

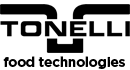

Multifunctional Mixer

This special execution of the Vertical Planetary Mixer is a multifunctional cooking/cooling system which, combined with specific tanks and thermal exchangers, becomes the first step of the pasteurization process.

The ingredients are pre-mixed in a first phase, then pasteurized at a high temperature with a possible resting time of some minutes.

Finally, the cream is vacuum-chilled down to medium temperature before being quickly pumped to the MU homogenizer.

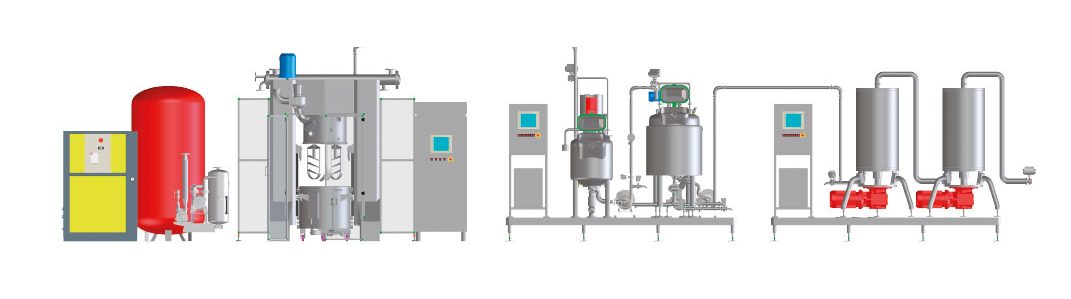

Aseptic homogenizer & aseptic buffer tank

In a second phase, the cream is batch-homogenized by means of an immersion homogenizer for some minutes. It is then pumped to the aseptic buffer tank, in a controlled environment.

Scraped Surface Cooling Exchangers

From here onwards the process becomes continuous, allowing the cream to be chilled down to the desired value, according to the final product requirements.

Moreover it can be further refined through an expressly shaped rotor.