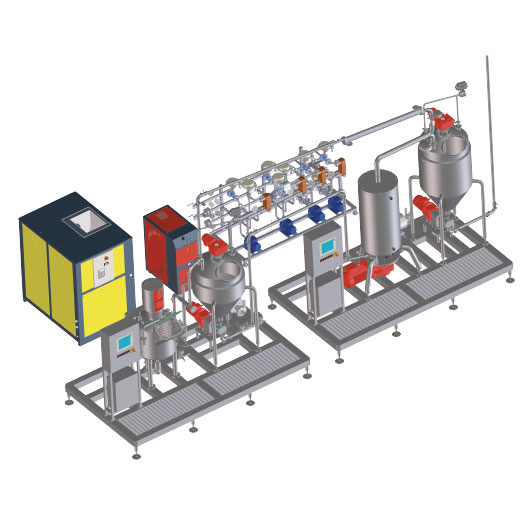

Tonelli Group has been urged by its major customers to study and develop systems capable to plasticize fats, while making the mixing of fat matters easier, quicker and more effective. With this in-bakery process, the plasticization can be made straight at the production site and the plasticized quantities can be adapted to the specific needs of each production line.

Fat plasticization

Tonelli’s high skill in fat plasticization comes from countless tests performed in its own state of the art Laboratory, using the most diversified types of fat matters.

Technology for plasticization

The plant for plasticization performs the process during the following steps:

1) Emulsion

The Centrifugal Mixer creates a stable emulsion oil/water very quickly.

1) First Buffering

The Buffer Tank keeps the oil/water emulsion at the right conditions of temperature and homogeneity for the plasticization phase.

3) Plasticization

The emulsion’s plasticization is performed by the Heat Exchanger, which achieves a fine crystallization, a low viscosity and a high stability.

4) Final Buffering

The plasticized fat is kept fluid and homogeneous into the maturing tank, until the next use.

The fat, after this process, is easy to transfer because of its fluidity and it is also easier to process with remarkable advantages for users.