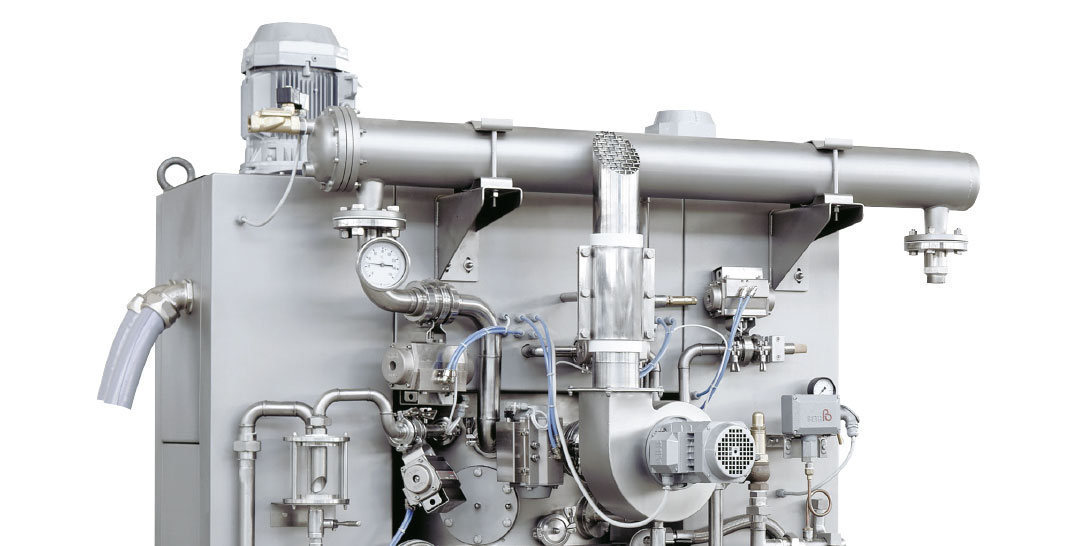

This special execution of the Vertical Planetary Mixer is a multifunctional cooking/cooling system.

It features a bowl with jacketed walls, allowing saturated steam circulation for cooking or water for cooling down the product in the same mixing chamber. Through the high vacuum it is possible to speed up the cooling phase or concentrate the blend, while mixing.

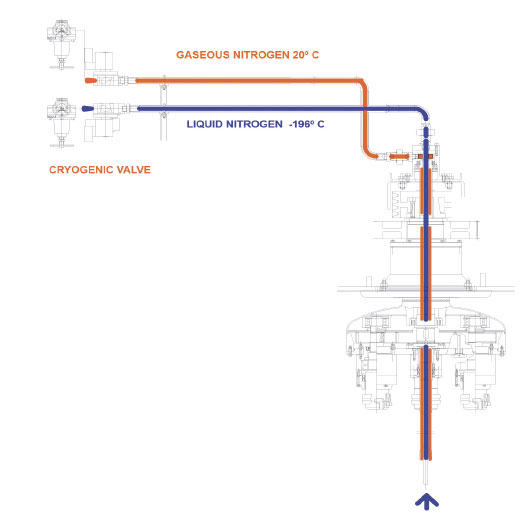

This system also allows to aerate the product with purified air under pressure and to use new cooling technologies – CO2, liquid nitrogen, glycol for the food industry.

Special mixing tools and scraper are specially designed and dedicated to for this extreme mixing environment. Safety is guaranteed by inox cages, protecting the operator from the whole steam circuit.

With its great flexibility, the Multifunctional Mixer realizes a great variety of products, such as pâte a chou, marzipan, dulce de leche, wafer, creams, sauces, jams, etc.