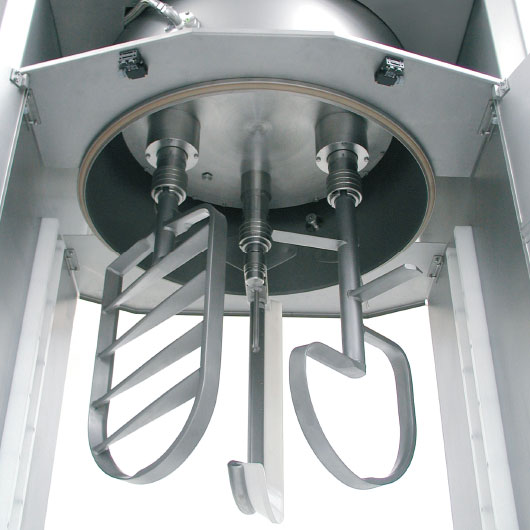

It is the machine by which Tonelli is known worldwide.

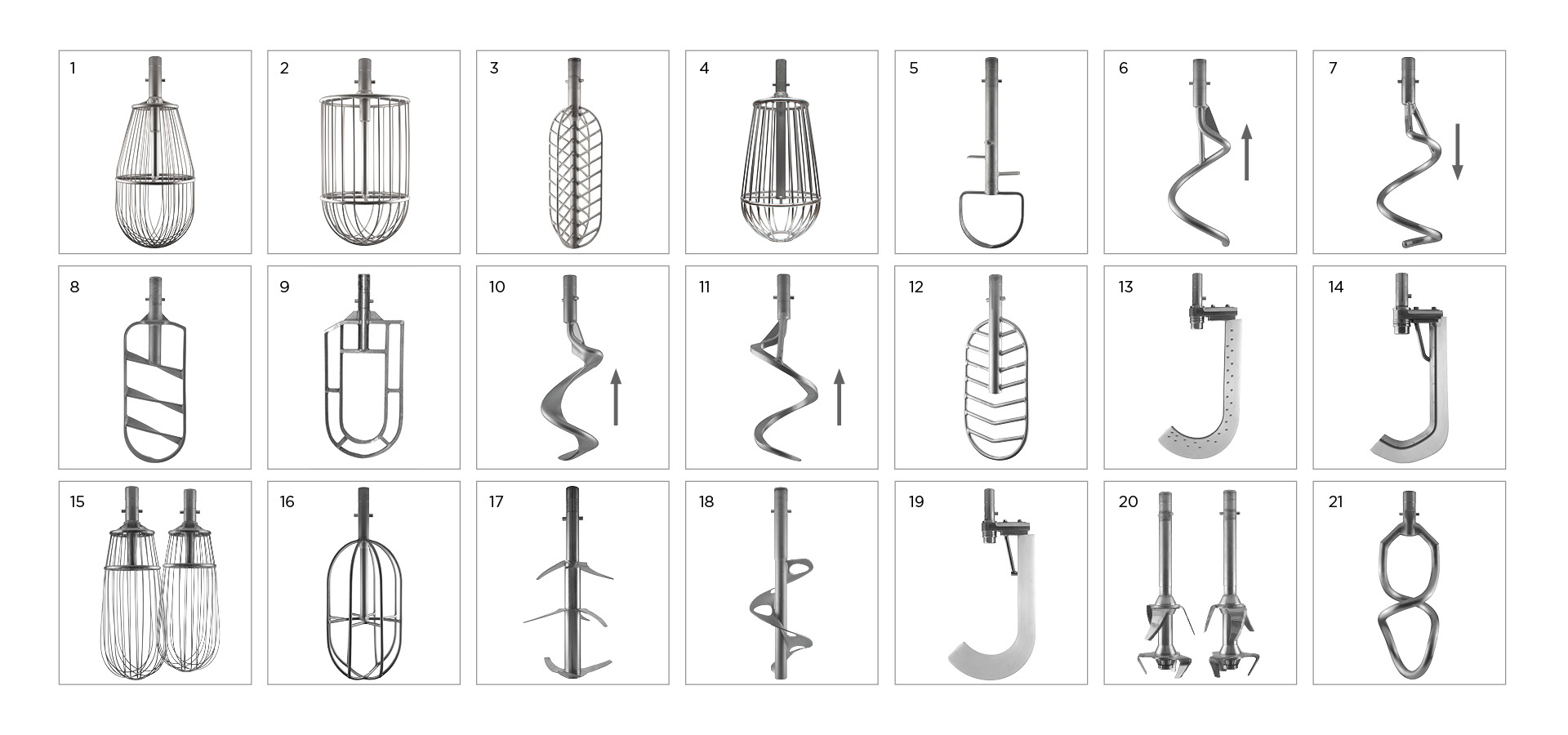

“The Planetary” through time has become a mixer that can be simple or complex, depending on the customer requirements; it is normally equipped with a pair of mixing tools and a scraper, suitable for a given application, but thanks to the interchangeability with other tools it may become a universal machine. The versatility is to allow manufacturers to achieve different operations using a single machine.